Square shafts with helical piles are usually constructed using small equipment such as a skid-steer loading machine or excavator with a hydraulic drive head. This approach not only speeds up the process of installation but also lessens the requirement for extensive ground preparation. The operator plays a crucial role in ensuring the piles are placed in a straight line, using both visual cues as well as assistance from ground workers.

One of the main elements of helical pile installation is achieving the required load capacity. This is the point where the connection between installation torque and load capacity becomes essential. Modern torque indicators, such as the Chance Digital Torque Indicator, are a key component in this process, offering accurate measurements, and removing the uncertainty that are associated with estimates of pressure in hydraulic systems.

The speed of operation during installation is crucial, usually ranging between 8 and 16 RPMs. This controlled speed will ensure that the pile is moving about 3 inches every revolution which is in line with the pitch of the helical plates. If the pile does not move as expected, adjustments like raising downward thrust or adding larger plates to prevent'spinning out' like a screw ripping its threads.

What Are Helical Piles Used For - Make It Right® Mike Holmes

Posted by on 2023-08-03

Multi-scale study of load-bearing mechanism of uplift piles based on model tests and numerical simulations | Scientific ... Nature.com

Posted by on 2023-04-19

Riviera - News Content Hub - 'Silent foundations' secure statement of feasibility Riviera Maritime Media

Posted by on 2021-01-25

A firm foundation when the ground is shaky University of Nevada, Reno

Posted by on 2021-01-27

The flexibility in helical piles are another factor contributing to their growing popularity. They can be used in a variety of soil kinds and conditions, including those difficult for conventional foundations. Their flexibility makes them an ideal option for sites that have a problem with soils, large water tables, or limited access. In addition, their design is able to be customized to meet specific load requirements and therefore, they are ideal for a variety of projects, from small houses to massive industrial projects.

In addition to their core advantages, helical piles are also equipped with additional advantages that solidify their position in modern construction. These include:

These additional features, coupled with their primary advantages, make Helical piles extremely flexible and effective foundation choice for a variety types of projects.

In the constantly evolving construction industry Helical piles have risen as a hidden treasure, with strengths that are changing the industry. This article sheds light on the advantages unique to helical pile installation, explaining the reasons why they are becoming increasingly popular for modern construction projects.

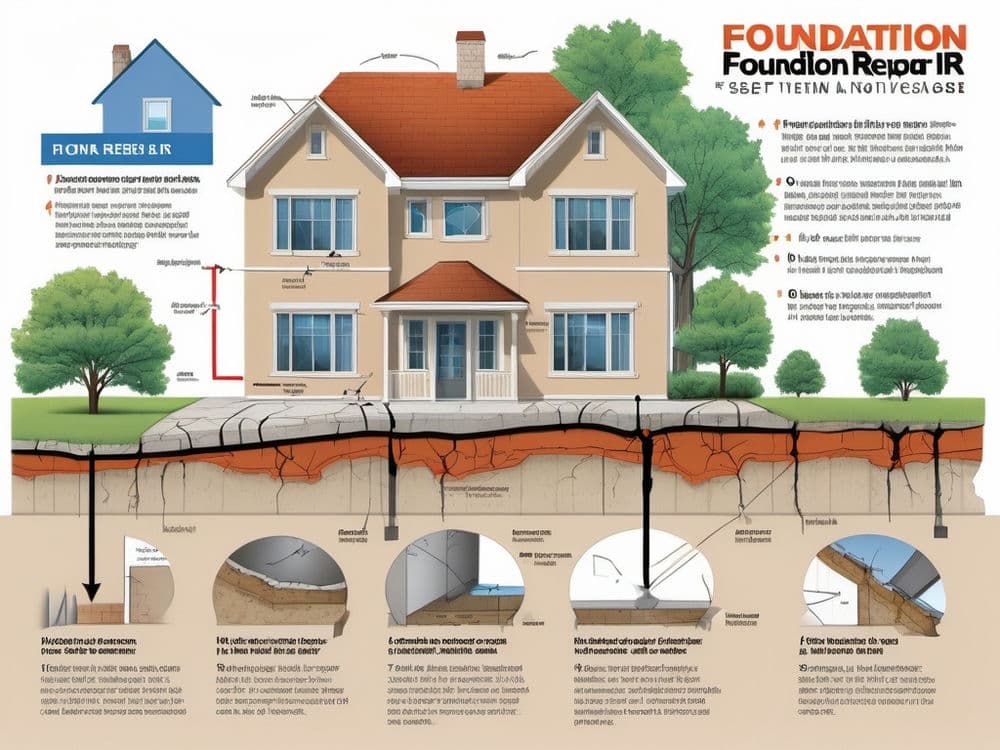

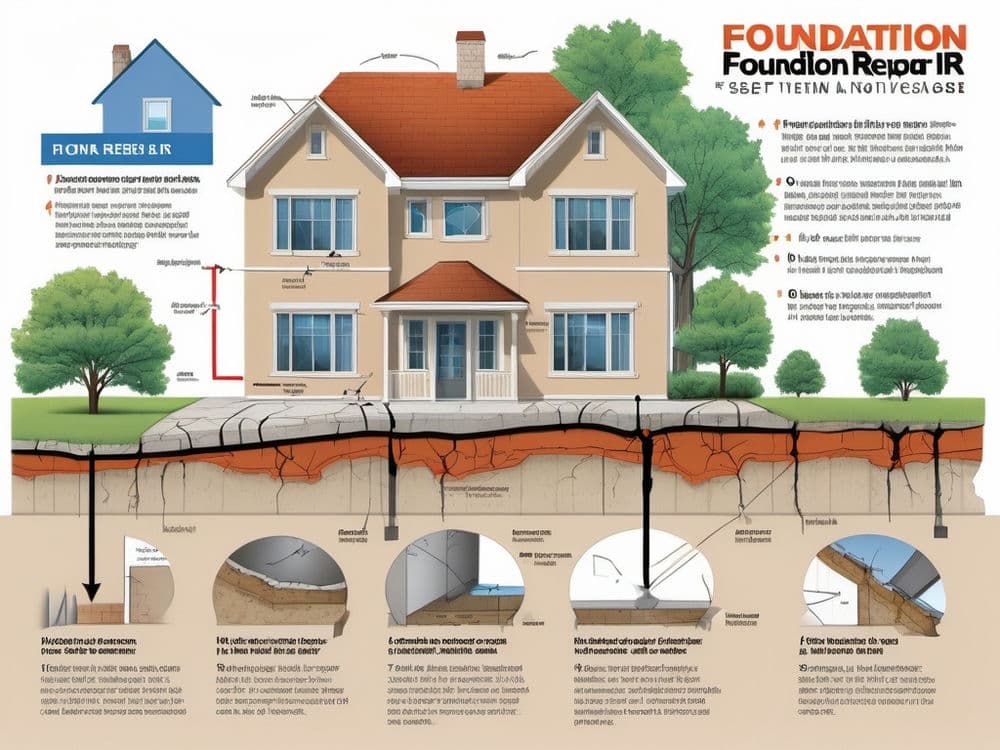

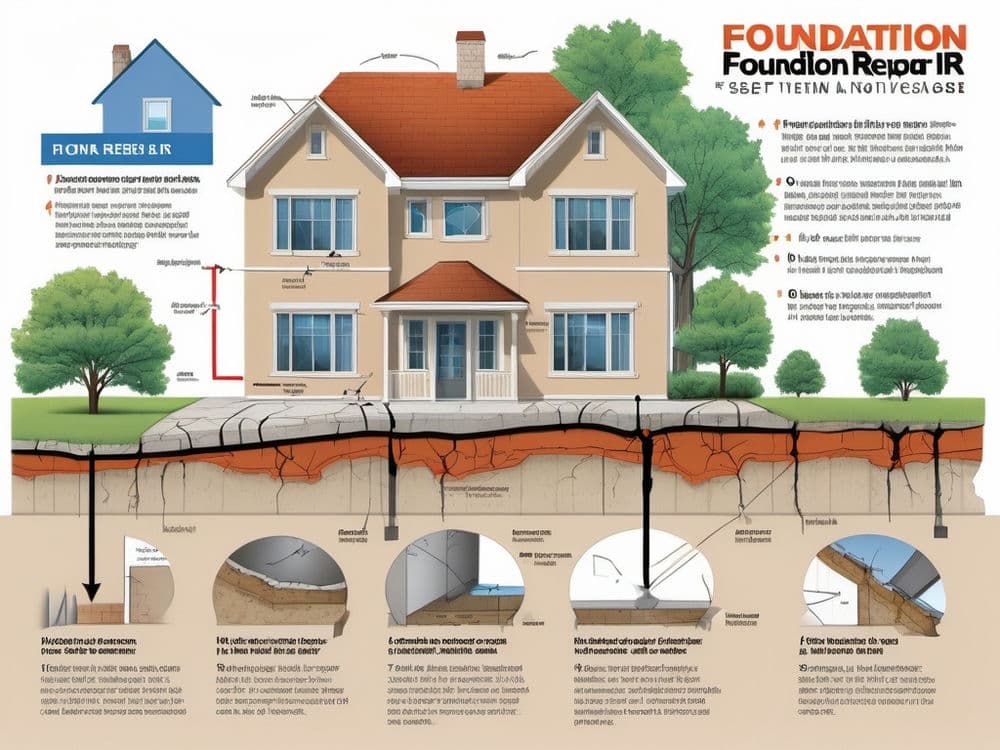

Helical piles, sometimes known as screw piles, are a deep foundation that is distinguished by its spiral-shaped plates, which are connected to a central steel shaft. This unique design allows for quick and efficient installation since the piles are literally installed to the earth. This is a sharp contrast to traditional foundation techniques and provides distinct benefits.

Based on the strength and foundation of the helical piles, their usage in construction projects provides a number of specific advantages. These are in the following manner:

These factors highlight the many benefits of using Helical piles in highlighting their role in improving efficiency, sustainability and cost-effectiveness of construction.